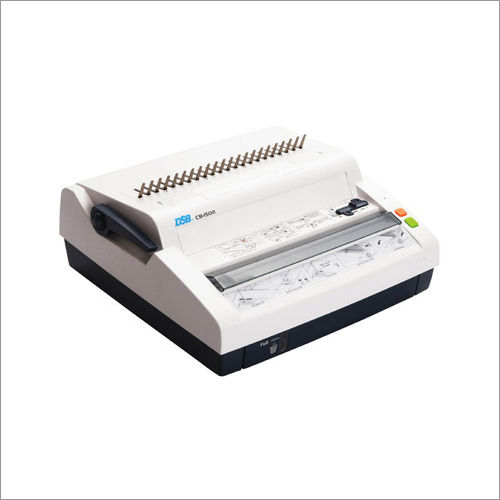

DSB Wire Giant Wire Binding Machine

Price 10000 INR/ Unit

DSB Wire Giant Wire Binding Machine Specification

- Hole Size

- 4 x 4 mm square holes

- Cover Thickness

- Up to 2 mm

- Binding speed

- Manual operation, average binding speed depends on user

- Usage & Applications

- Office, school, copy shop, professional document binding

- Paper Type

- A4, Letter, and smaller sizes

- Hole Spacing

- 3:1 pitch (8.47 mm)

- Type

- Manual wire binding machine

- Material

- Metal and durable plastic construction

- Dimension (L*W*H)

- 390 x 320 x 170 mm

- Weight

- 7.5 kg

- Power Source

- Manual

- Compliance

- CE certified

- Maximum Binding Width

- 300 mm

- Binding Element

- Twin loop wire, 34 holes (A4 size, 3:1 pitch)

- Punching Type

- Manual lever-action

- Color

- Gray/blue

- Maximum Punching Capacity

- 15 sheets (80gsm) per time

- Environment

- Suitable for desktop use

- Adjustable Margin Depth

- Yes, selectable positions

- Noise Level

- Silent operation

- Wire Closer

- Integrated wire closer

- Binding Capacity (Sheets)

- 120 sheets (80gsm paper)

- Chip Tray

- Removable for easy cleaning

DSB Wire Giant Wire Binding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 5 Minutes

- Main Domestic Market

- All India

About DSB Wire Giant Wire Binding Machine

Driven by a vision to achieve significant growth in this industry, we bring forth a wide series of DSB Wire Giant Wire Binding Machine. It is ideal for use in large offices or copy shops. Our presented machine is to secure papers together. DSB Wire Giant Wire Binding Machine is featured with excellent functionality, low maintenance and easy usage. It is used for binding double loop wire notebooks and increases the production efficiency.

Specification :

| Binding System | 34 Loops O-Wire |

| Brand | DSB |

| Machine Dimension | 440 x 265 x 145 mm |

| Max Bind | 16 mm (125 Pages) |

| Max Punch | 15 Sheets |

| Special Function | Wire Closing Device |

| Weight | 6 kg |

| Machine Type | Wiro Binding Machine |

| Model Name/Number | Wire Giant |

High-Capacity Wire Binding for Professional Needs

The DSB Wire Giant Wire Binding Machine is engineered to handle demanding workloads, with a binding capacity of 120 sheets and a punching capability of up to 15 sheets per lever action. Its sturdy construction and silent operation make it ideal for busy offices, copy shops, and educational institutions. The machine supports a binding width of up to 300 mm and can accommodate a range of cover thicknesses, making your reports and presentations look polished.

Precise, Customizable Punching and Binding

Experience superior control with selectable margin depth adjustments, ensuring the binding suits each project's needs. The machine's 34-hole layout and 3:1 pitch spacing (8.47 mm) pair with 4x4 mm square punches for uniform results. The integrated wire closer further streamlines your workflow, enabling seamless, professional wire finish every time, while the removable chip tray simplifies cleaning.

Simple, Efficient, and User-Friendly Operation

Designed with usability in mind, this manual binding solution provides straightforward operation with its lever-action punch and easy wire insertion. Its compact, desktop-ready size makes it suitable for various work environments, while silent operation ensures minimal disruption. The machine is CE-certified for safety and quality, supporting reliable long-term use in India's busy workplaces.

FAQ's of DSB Wire Giant Wire Binding Machine:

Q: How do I operate the DSB Wire Giant Wire Binding Machine for binding documents?

A: To use the DSB Wire Giant Wire Binding Machine, first load up to 15 sheets (80gsm) at a time and punch holes using the manual lever. After preparing your document stack (up to 120 sheets), insert the twin loop wire into the punched holes, then use the integrated wire closer to finish and secure your binding.Q: What sizes and types of paper can this wire binding machine accommodate?

A: This machine is designed primarily for A4 size paper, but it also supports letter and smaller sizes. It can bind a wide range of documents, including reports, presentations, booklets, and covers with thicknesses up to 2 mm, making it flexible for various professional requirements.Q: Where is the DSB Wire Giant Wire Binding Machine best suited for use?

A: The machine's sturdy, silent design makes it ideal for desktop use in offices, schools, copy shops, and any setting where frequent document binding is required. Its compact dimensions (390 x 320 x 170 mm) ensure it fits comfortably on most work surfaces.Q: What is the process for adjusting the punching margins on this binding machine?

A: You can easily adjust the margin depth on the machine using the selectable settings, allowing you to customize the binding edge to suit your document's requirements and ensure durability and a neat finish.Q: How often should I clean the chip tray, and how is it done?

A: For optimal performance, empty the removable chip tray regularly, especially after multiple binding sessions or when you notice it filling up with paper debris. Simply slide out the tray, dispose of the punched chips, and reinsert it.Q: What are the main benefits of using this wire binding machine for businesses or schools?

A: Key benefits include the ability to quickly and professionally bind large documents, enhance document durability, and improve presentation quality. Manual operation means no power source is needed, making it cost-effective, environmentally friendly, and convenient for any workspace.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Binding Machine Category

Electric Binder Machine

Price 35000 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Spacing : 8.5 mm

Paper Type : A4, Letter, Legal

Power Source : Electric

Usage & Applications : Office, Commercial, School, Printing Shops

DSB CB 240 Manual Comb Binding Machine

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Spacing : 9.42 mm (A4 standard spacing)

Paper Type : 80 gsm to 150 gsm (standard copy or binding paper)

Power Source : Manual (No power required)

Usage & Applications : Ideal for office, school, and personal document binding

Deluxe Coil 46E-30 Multi Functional Binding Machine

Price 95000 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Spacing : 8.47 mm (standard coil spacing)

Paper Type : Paper, PVC covers, Cardboard

Power Source : Electric

Usage & Applications : Ideal for office, copy shop, print shops, and educational institutions

CB-150 E Electric Comb Binding Machine

Price 40000 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Spacing : 14.3 mm

Paper Type : A4, Letter size paper

Power Source : Electric

Usage & Applications : Office, school and copy shop comb binding

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free