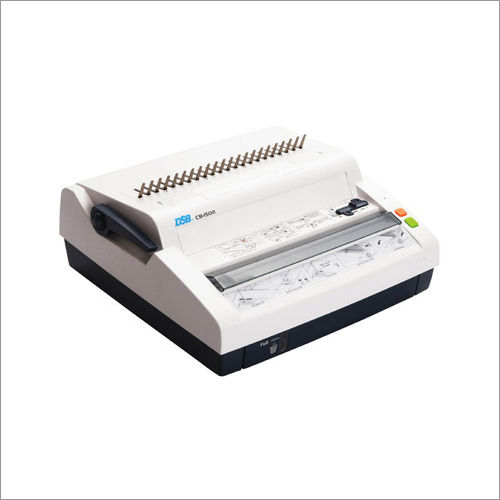

Anybind Combination Binding Machine

Price 20000 INR/ Unit

Anybind Combination Binding Machine Specification

- Usage & Applications

- Suitable for office, school, and printing shops for comb and wire binding

- Binding speed

- Up to 250 books/hour

- Cover Thickness

- Up to 450 gsm

- Hole Size

- 4 x 4 mm square holes

- Hole Spacing

- 8.47 mm

- Paper Type

- A4, Letter, Legal size

- Type

- Manual comb and wire binding machine

- Material

- Metal body with high-grade ABS plastic components

- Dimension (L*W*H)

- 400 x 300 x 150 mm

- Weight

- 8.5 kg

- Power Source

- Manual operation (no electricity required)

- Color

- Gray and black

- Punching Method

- Manual lever

- Number of Holes

- 21 holes (comb), 34 holes (wire)

- Handle Type

- Ergonomic dual handle for punch and bind

- Punching Capacity

- Up to 20 sheets (80 gsm) per punch

- Max Binding Width

- up to 300 mm

- Adjustable Margin Depth

- Yes, 2.5, 4.5, 6.5 mm

- Binding Capacity

- 500 sheets (comb), 120 sheets (wire)

- Compatibility

- Plastic comb and 3:1 wire

- Waste Drawer

- Integrated

Anybind Combination Binding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Anybind Combination Binding Machine

Having a positive quality management system, we are able to provide a broad arrangement of Anybind Combination Binding Machine. It is designed to do the work of two or three machines. In other words, provided machine is availed in numerous specifications according to the demand of customers. Our offered binding machine is used over the globe and are highly appreciated for their higher performance. It performs at high productivity and maximum operation.

Dual Functionality for Enhanced Productivity

The Anybind Combination Binding Machine integrates both comb and 3:1 wire binding capabilities in a single device. It features 21 holes for combs and 34 for wires, enabling users to switch binding types efficiently. This versatility makes it ideal for dynamic office work environments, schools preparing varied materials, or print shops delivering client projects swiftly.

Sturdy Build with Ergonomic Design

Constructed with a metal body and reinforced by high-grade ABS plastic components, the machine promises durability and longevity. The ergonomic dual handles are specially designed for easy manual punching and binding, reducing operator fatigue even during high-volume tasks. The integrated waste drawer adds convenience, ensuring a tidy workspace throughout the binding process.

FAQ's of Anybind Combination Binding Machine:

Q: How do I use the Anybind Combination Binding Machine for comb and wire binding?

A: Start by selecting your preferred binding method-comb or wire-then adjust the margin depth as required (options are 2.5, 4.5, or 6.5 mm). Insert up to 20 sheets (80gsm) for punching using the manual lever. For binding, place up to 500 sheets for comb binding or 120 sheets for wire binding, then operate the corresponding handle to securely bind your document.Q: What types and sizes of paper are compatible with this binding machine?

A: The Anybind Combination Binding Machine accommodates A4, Letter, and Legal sized paper. It is designed to punch and bind documents with a maximum width of up to 300 mm and a cover thickness of up to 450 gsm, providing flexibility for various document formats.Q: When is it advisable to adjust the margin depth setting?

A: Adjust the margin depth based on the thickness of your document. A deeper margin (up to 6.5 mm) is recommended for larger or thicker documents to ensure the punched holes are strong and not prone to tearing, while a smaller margin is suitable for thinner documents.Q: Where can I use this binding machine effectively?

A: This binding machine is well-suited for office document preparation, school projects, and printing shop services. Its versatility and manual operation make it ideal for distributor, exporter, manufacturer, retailer, service provider, supplier, trader, and wholesaler settings across India that require reliable, electricity-free binding solutions.Q: What is the punching and binding process for this machine?

A: Manually insert the sheets into the punch slot and operate the lever to punch up to 20 sheets at a time. Collect the punched sheets, align them on the binding mechanism (comb or wire), and then use the ergonomic handle to complete the binding process. The integrated waste drawer ensures easy disposal of paper trimmings.Q: Can the machine handle high binding speeds and frequent use?

A: Yes, the Anybind can bind up to 250 books per hour, making it suitable for high-volume environments. Its robust construction and dual handle design ensure reliable performance, even with continuous manual operation.Q: What are the main benefits of using this binding machine?

A: Users benefit from its manual, electricity-independent operation, versatile support for various binding methods and paper sizes, sturdy construction, and ergonomic design. This enhances productivity, reduces operational fatigue, and offers cost-effective document finishing in professional settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Binding Machine Category

Deluxe Coil 46-23 Spiral Binding Machine

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 13 kg

Material : Other Material, Heavy Duty Metal Body

Type : Other Binding Supplies, Manual and Electric Spiral Binding Machine

Paper Type : All standard office papers

DSB WR 200 - Wire Binding Machine

Price 38000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : Approx. 6 kg

Material : Other Material, Metal and durable plastic

Type : Other Binding Supplies, Wire Binding Machine

Paper Type : A4, Letter, Legal

Electric Binder Machine

Price 35000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 14.5 kg

Material : Other Material, Highgrade Metal and ABS Plastic

Type : Other Binding Supplies, Electric Comb Binder

Paper Type : A4, Letter, Legal

CB-150 E Electric Comb Binding Machine

Price 40000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 12.5 kg

Material : Other Material, Metal and ABS plastic body

Type : Other Binding Supplies, Electric Comb Binding Machine

Paper Type : A4, Letter size paper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free